“Nowhere” and decide what looks the best. If so, look at the preview tab in Cura closely and compare “Everywhere” vs. For example, if you are trying to print out some small raised text. Leave this at everywhere, unless you are getting some weird extruder paths. Zig-Zag could add a little strength in some cases, but sometimes doesn’t look as nice. Concentric can end up being weak and could cause a print to fail or look sloppy except in specific situations. However “Lines” is a little easier and more accurate for your printer and tends to be a little stronger. Generally leave this at lines except for in a few specific cases where you might be printing a circular object and then Concentric could be better. Usually keep it around 0.8 to 1 mm total top/bottom thickness, but if you have a large unsupported area that may not print well at first, I would increase that up to around 1.6mm thickness. If you have some extreme overhangs, lots of supports, or supports that might not be sufficient, increasing this can save the top of your print from looking very sloppy. Similar to wall thickness, only on the top/bottom (Z axis) instead of sides. However in comparing sliced results with this at 0 or 1 I usually don’t see much difference. It could be useful if you want to improve the finish on the top surfaces of your prints–especially on flat prints. I usually leave this setting at 0 and just add more Top Layers if I think it is needed. Wall Line Count / total Wall Thickness has a huge impact on print time. For a toy or decorative statue, 1.2mm total wall thickness is a good balance when used along with 10-20% or more infill setting. Structural or weight-bearing prints will want more like 5 walls (2.0mm total thickness) and 30-100% infill, but that uses a lot more time and filament. A thin decorative vase could use a thin total wall thickness like 0.8mm (2 walls), but may break easily when dropped or squeezed. Generally you will want your prints to have at least 1.2 mm total Wall Thickness in order to be sturdy when handled. For a 0.4mm nozzle that means the total Wall Thickness would usually be: 0.8mm, 1.2mm, 1.6mm, or 2.0mm.Your total Wall Thickness should be a multiple of your nozzle size.

Line Width should usually be the same as your nozzle size (0.4mm nozzle size is assumed here.).Each individual Wall will be the same thickness as your Line Width.You could increase slightly to 101% to help with bed adhesion, but this shouldn’t be necessary with a well leveled bed.

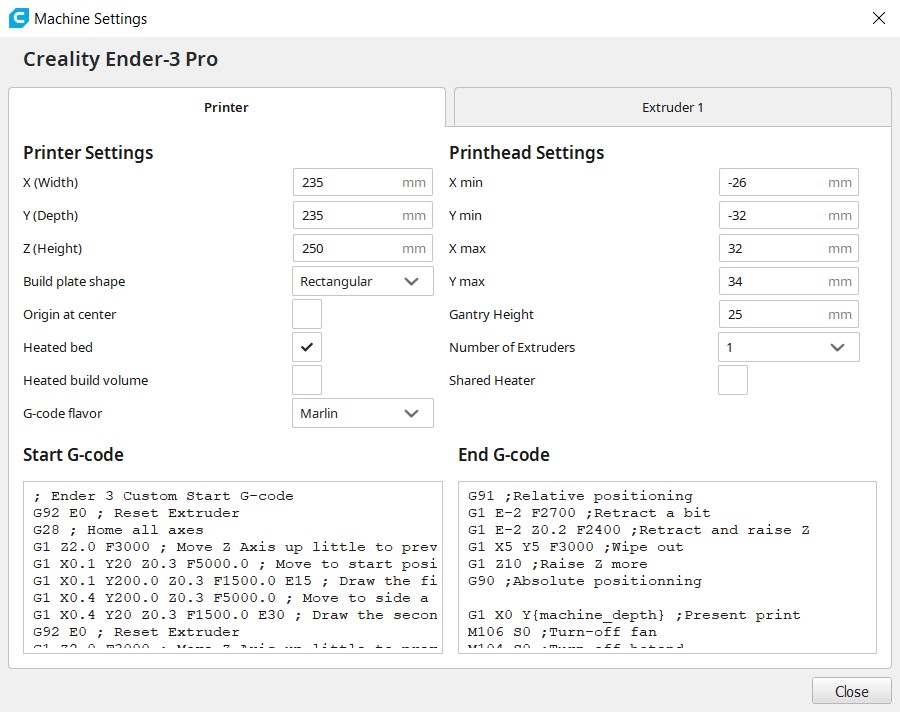

#Ultimaker cura ender 3 v2 settings install#

If you install a different sized nozzle, be sure this is updated to match! Some other common nozzle sizes are 0.2, 0.6, 0.8, etc. Leave it set to default, the same as the width of your nozzle. As a general rule add 0.08 to your layer layer height, or use double your layer height if using fine detail like 0.12 layer height. Thicker initial layer height helps bed adhesion. If you want even thicker layer heights, step up to a 0.6 or 0.8mm nozzle first. Stick to 0.12 (fine detail) or 0.2 (standard detail) usually.

The below settings assume you are using a standard 0.4 mm nozzle that comes installed by default on most printers.Cura Settings Cheat Sheet for CR-10S & Similar 3D Printers:

0 kommentar(er)

0 kommentar(er)